Earthblock making – FASE Diary Week 3

This week has been exciting and we have some great progress to share!

From having just the outline of the shelter prepped last Friday, with the help of the team at CIDO we managed to not only complete the shelter build but also our field compression testing and start on the brick making!

The shelter build was fantastic and involved a number of people and materials to take it to completion. We bought wood, borrowed spades and help from two different local farmers, bought sustainable roof materials made from local grass called “Tight” Roof and help from Sarin, Sokphea and Poeuch at CIDO.

On Monday we finished with the main structure in place, which consisted of eight strong wood logs dug 0.5m in the ground to outline the skeleton of the building.

On Tuesday we finished with further supporting and strengthening timber straights, walls made from thick waterproof plastic sheets (donated by a local shop) and our testing rig firmly in place within the shelter.

On Wednesday, the roof was finished and we started Round 1 of the field compression tests…

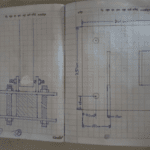

The test rig is built up of a single metal rod 1.5m in length with a metal “pin” 2cm in diameter welded on at 0.5m. This rod is then hinged on a bolt and metal blacking plate to allow 180 degrees movement. A thick wall piece of wood is used to bolt the backing plate into, so that it can be dug into the ground and hold its place when carrying out the testing.

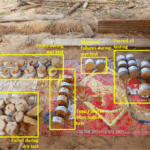

Before we could begin testing, a testing criteria and strategy was established. The recommended strength for bricks in a single story building is approximately 2Mpa and double story 4Mpa.

The final earth bricks in the construction of the Agri Tech Centre will only be used as single story loading however to account for any future work or developments we tested to 4Mpa also. There is also the factor of the bricks getting wet and the subsequently the remaining strength after. After a bit of discussion with the engineers at Burro Happold and Ed at SAWA, our final testing plan was as follows:

Round 1 Testing

-Dry Compression Test upto 2Mpa

-Bucket (soak) test for 12 hrs or more

Round 2 Testing

-Wet Compression Test at 2Mpa and 4Mpa

-Make test walls and carry out drop tests and bridge tests

We calculated that approximately 19.3kg weight hung onto the end of the metal rod would result in a 2Mpa force being applied through the 2cm diameter metal pin onto the sample earth blocks. And double the weight equaled double the force of 4Mpa.

On Thursday, we finished all the compression testing and collated our results to share with our international team (via whatsapp). The key highlights from the testing were:

-The earth-only samples passed the dry testing but immediately fell apart in the water during the bucket test!

-There was measurable variance in the earth samples from the three different locations with earth sample from location 3 being generally the weakest.

-Cement mix ratios of 8, 11 and 15% tested the best with all the earth samples which meant that it didn’t matter where the earth came from, the samples were all strong enough for both 2MPa and 4Mpa.

Having the test results allowed us to narrow down the range of viable cement/earth ratios we could use to begin making the full size earth bricks.

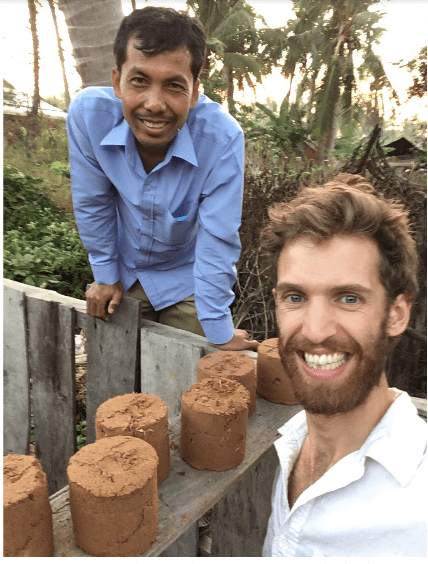

On Friday we began mixing up the first batch of test bricks (a mix of earth with 8% cement). After a full day of trialing different mixing and molding methods we successfully produced 32 bricks. These we now have to leave in the shelter (protected from the weather) to cure and reach their full strength.

Next week we need to aim to complete round 2 of testing which means building some test walls and carrying out some drop tests and bridge tests. This will hopefully help us in narrowing down the choices a bit further and finish with the best earth brick mix possible for the Agri-tech centre construction!

Tom & Sakshi

You can still contribute towards this project via this link: https://mydonate.bt.com/events/greenshoots10nov